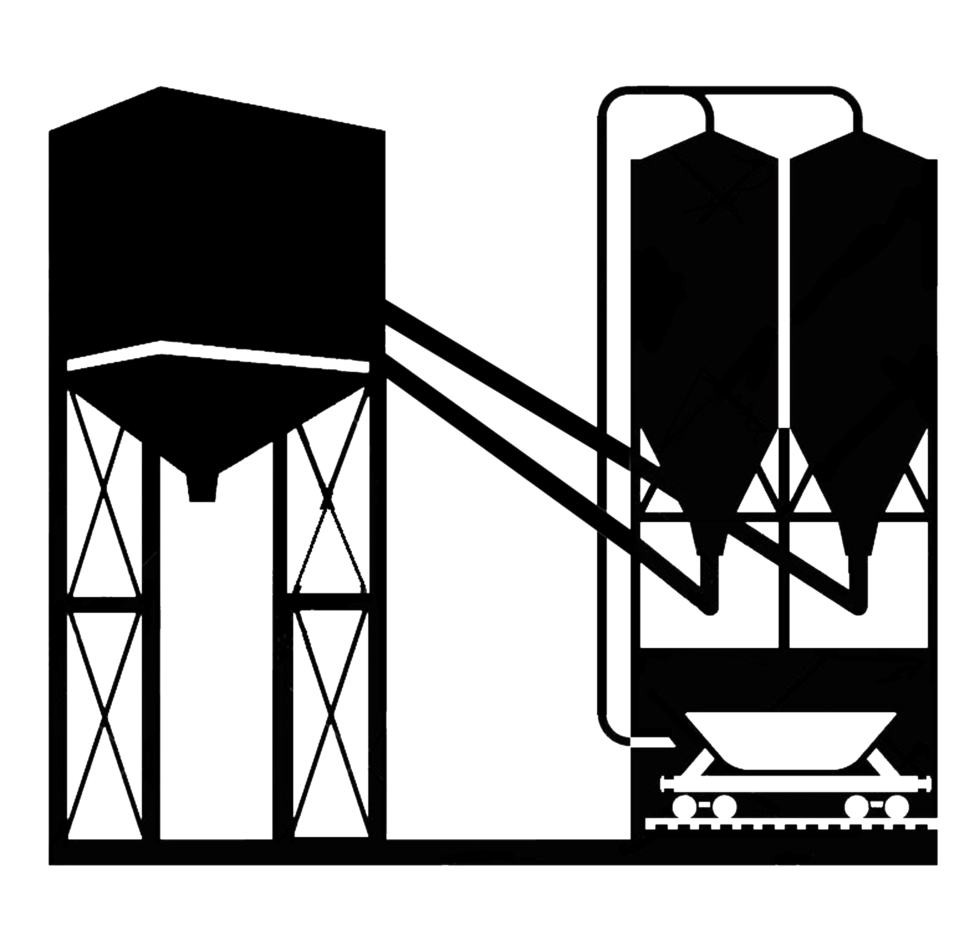

Vega® rubber hoses normally used for conveying mortar or concrete in general, find application in various fields, from the agricultural sector to the construction industry, to the naval and mining sectors. They stand out for their high resistance to abrasion and excellent flexibility.

STANDARD

Vega® rubber hoses, made in Italy, are manufactured with a special abrasion-resistant rubber inside. The four steel layers give the hose excellent resistance to both abrasion and crushing while maintaining a good radius of curvature and extremely low weight. The fittings, the most stressed part of the tube, are made of hardened steel. Particular attention is paid to the pressing of the fitting to the pipe, completely eliminating the internal step. We can supply hoses from 50 to 150 mm with a working pressure of 100 bar.

| HOSE | black conductive NR rubber – abrasion resistant |

|---|---|

| FITTING HARDNESS | > 60 HCR |

| REINFORCEMENT | high tensile steel cords |

| COVER | black conductive SBR/NR – abrasion and ozone resistant |

| USE | high pressure concrete pumping |

| SAFETY FACTOR | 2:1 |

| TEMPERATURE | -30 °C +80°C (-22°F +176°F) |

| mm | inch | mm | inch | bar | psi | bar | psi | mm | inch | kg/m | lb/ft |

| 51 | 2 | 69 | 2.72 | 100 | 1500 | 200 | 2900 | 380 | 15.0 | 2.13 | 1.435 |

| 63 | 2 ½ | 85 | 3.35 | 100 | 1500 | 200 | 2900 | 400 | 15.8 | 3.34 | 2.245 |

| 76 | 3 | 100 | 3.94 | 100 | 1500 | 200 | 2900 | 400 | 15.8 | 4.54 | 3.055 |

| 102 | 4 | 128 | 5.04 | 100 | 1500 | 200 | 2900 | 550 | 21.7 | 7.02 | 4.72 |

| 127 | 5 | 153 | 6.03 | 100 | 1500 | 200 | 2900 | 700 | 27.6 | 9.44 | 6.34 |

| 152 | 6 | 184 | 7.24 | 100 | 1500 | 200 | 2900 | 800 | 31.5 | 13.78 | 9.265 |

CONICAL

A particular model of rubber hose characterized by two different diameters at its ends is available: DN100-DN125. The difference of the two diameters allows the application on machines with 125 mm piping allowing the concrete to flow in smaller formworks. This type of hose facilitates concrete pouring by reducing the size without having to apply heavy and rigid steel reductions, while maintaining the manageability of the rubber hose.

| HOSE | black conductive NR rubber – abrasion resistant |

|---|---|

| COVER | black conductive SBR/NR – abrasion and ozone resistant |

| FITTING | cemented |

| USE | high pressure concrete pumping |

| LENGTH | 3.500 mm |

| WORKING PRESSURE | 85 bar |

| BURST PRESSURE | 180 bar |

| WEIGHT | 28 kg |

ANTI-WHIP HOSE

Our research for new products is always safety-oriented and is made in compliance with the law. That’s why, RM® decided to add a new product to its rubber hoses range: the Anti-Whip Hose. Our Vega® anti-whip hoses are made of special textile plies and NR/SBR rubber, abrasion and weathering resistant.

This new anti-whip hose can:

- absorb shocks and vibrations

- prevent the whip effect

- make concrete pumping operations safer

At the moment, this hose is available in DN125, 4mt long version.

| Code | Description |

|---|---|

| TLF125.55L4000V/1 | anti-whip hose DN125 with nr.1 collar 5"1/2 |

TECHNICAL SPECIFICATION

| HOSE | black conductive rubber NR/SBR hard – abrasion resistant |

|---|---|

| RENFORCEMENT | special textile plies |

| COVER | black conductive rubber hard abrasionand weathering resistant |

| USE | high pressure concrete pumping |

| TEMPERATURE | -40 °C to + 70°C |

| WORKING PRESSURE | 100 bar |

| BURST PRESSURE | 200 bar |

| mm | inch | mm | inch | bar | psi | bar | psi | kg/m | lb/ft |

| 100 | 4 | 127 | 5.00 | 100 | 1500 | 200 | 2900 | 5.73 | 3.85 |

| 125 | 5 | 152 | 5.99 | 100 | 1500 | 200 | 2900 | 6.99 | 4.70 |

SAFETY AND USE INFORMATION

USER RESPONSIBILITY

The service life of Vega® rubber hoses mainly depends on the dedicated use. Equipment and systems where the rubber hose is installed must be designed in conditions of total safety. Since our hose can be designed for different applications, RM® cannot guarantee the proper functioning of the product for all situations. The analysis of the technical aspects related to specific uses must be performed by the users when choosing the product that meets their requirements. So, in relation to the variety of operating conditions and applications of the Vega® rubber hose, the user is the sole responsible for the final choice of the product, suitable to satisfy the performance and safety requirements for the application. The information and technical data shown in the attached data sheets must be examined by users with appropriate technical skills and knowledge. RM® is not responsible for other uses, identified by the end user, that are different from the one shown in the proper product data sheet. An inappropriate choice of the product or a failure to follow the technical features of the product for installation, use, maintenance and storage of the hoses may lead to hose failure, premature wear and cause material damage and/or serious injury to people. These recommendations are made in accordance to the international standard ISO 8331, “Plastic and rubber hoses and hose assemblies – Guidelines for selection, storage, use and maintenance.” For safety reasons, never exceed the working pressure indicated in the product data sheet.